What Is Chemical Blending Toll Processing and When Do You Need It?

Chemical blending toll processing plays a critical role in modern chemical manufacturing and supply chain management. As companies face increasing pressure to control costs, maintain consistent quality, meet regulatory requirements, and scale production efficiently, outsourcing specific production steps has become a strategic advantage. One of the most common and valuable outsourced services in the chemical industry is chemical blending toll processing. In its simplest form, chemical blending toll processing allows a company to retain ownership of its formulations and raw materials while leveraging a specialized third-party facility to perform blending, packaging, quality control, and related services. This model enables manufacturers, distributors, and brand owners to bring products to market faster and more reliably without the burden of capital investment in equipment, labor, and infrastructure.

Understanding when and why chemical blending toll processing makes sense requires a clear look at what the service entails, how it works from start to finish, and what business challenges it is designed to solve. Whether you are launching a new product, experiencing capacity constraints, or seeking tighter quality control, toll blending can be a powerful solution when implemented with the right partner.

What Is Chemical Blending Toll Processing?

Chemical blending toll processing is a contract service in which a specialized facility blends chemical ingredients according to a customer provided formulation or specification. The customer typically supplies the raw materials, or in some cases authorizes the toll processor to source them, while retaining ownership of the finished product. The toll processor is paid a fee for performing the blending, handling, quality testing, and often packaging and labeling.

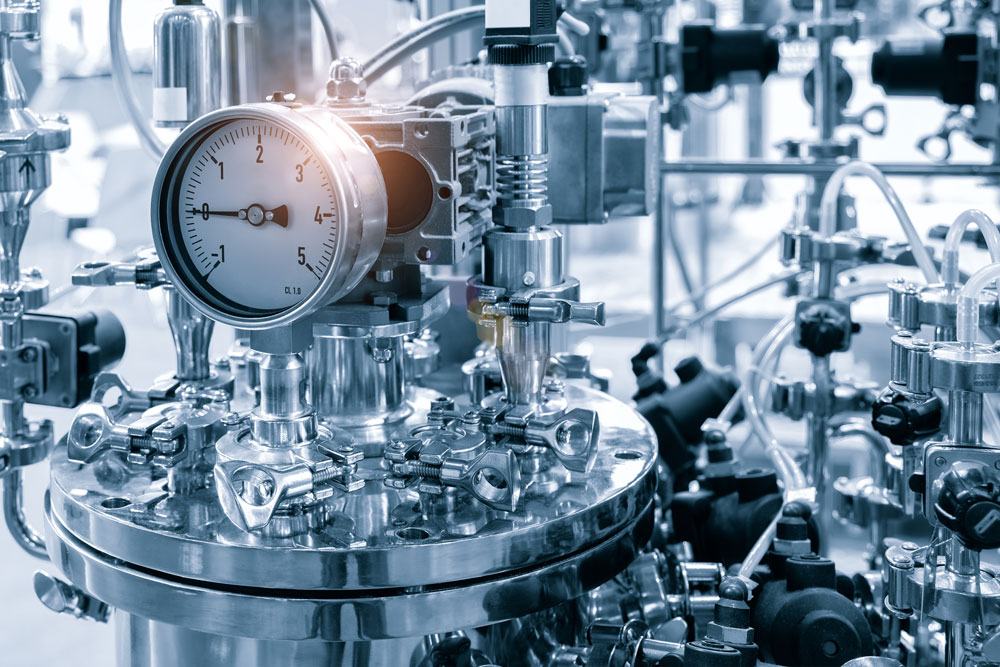

Unlike full scale manufacturing ownership models, chemical blending toll processing allows companies to focus on product development, sales, and distribution while outsourcing the operational complexity of blending. Toll processors invest in industrial mixers, tanks, automation systems, and trained technical staff that would be costly and time consuming for many companies to replicate in house.

Key characteristics of chemical blending toll processing include:

- Customer owned formulas and intellectual property

- Blending performed to exact specifications

- Scalable batch sizes from pilot to commercial volumes

- Industrial grade equipment designed for consistency and safety

- Optional services such as raw material sourcing, packaging, labeling, and logistics

This approach is widely used across industries including specialty chemicals, coatings, adhesives, cleaners, lubricants, agricultural chemicals, and industrial fluids.

Chemical Blending Toll Processing vs Contract Manufacturing: What’s the Difference?

Although the terms are sometimes used interchangeably, chemical blending toll processing and contract manufacturing are not the same. Understanding the distinction is important when selecting the right outsourcing model.

Chemical blending toll processing typically means that the customer owns the formula and often the raw materials. The toll processor provides labor, equipment, quality systems, and processing expertise. The customer maintains control over product specifications and branding while paying a processing fee.

Contract manufacturing, on the other hand, often involves the manufacturer owning or co developing the formulation, sourcing raw materials, and producing the finished product under a private label or branded arrangement. In this case, the contract manufacturer may have greater control over sourcing decisions and process parameters.

In practical terms, toll processing is often preferred when:

- Intellectual property protection is a priority

- Exact formulation control is required

- The customer already has approved raw material suppliers

- Flexibility and scalability are needed without long-term manufacturing commitments

Contract manufacturing may be a better fit when a company wants a turnkey solution that includes formulation development and sourcing. Many facilities offer both services, but it is important to clarify which model best aligns with your business objectives.

How Does Chemical Blending Toll Processing Work from Start to Finish?

While each project has unique requirements, chemical blending toll processing generally follows a structured and repeatable workflow designed to ensure safety, quality, and consistency.

1. Initial Consultation and Technical Review

The process begins with a technical discussion between the customer and the toll processor. During this phase, key details are reviewed including:

- Chemical formulation and specifications

- Target batch sizes and production volumes

- Raw material handling requirements

- Safety, regulatory, and environmental considerations

- Packaging and labeling needs

- Quality control and testing protocols

This step allows the toll processor to confirm feasibility and recommend any process optimizations.

2. Quoting and Project Approval

Based on the technical review, the toll processor provides a detailed quote covering blending costs, setup fees, testing, packaging, and any additional services. Lead times and scheduling expectations are also defined. Once the quote is approved, the project moves into planning and scheduling.

3. Raw Material Receipt and Verification

Raw materials are either shipped by the customer or sourced by the toll processor on the customer’s behalf. Upon arrival, materials are inspected and verified to ensure they meet the required specifications. Proper documentation, labeling, and storage protocols are followed to maintain traceability and compliance.

4. Batch Preparation and Blending

Blending is performed using industrial equipment suited to the product’s viscosity, reactivity, and volume requirements. This may include ribbon blenders, paddle mixers, high shear mixers, or tank blending systems. Operators follow documented procedures to ensure precise ingredient addition, mixing times, and temperature controls.

5. In Process Quality Control

During blending, in process checks may be performed to confirm homogeneity, appearance, or other critical parameters. These checks help ensure that the final product will meet all specifications before packaging.

6. Final Testing and Release

After blending is complete, samples are taken for laboratory testing as defined by the customer’s quality requirements. Common tests include viscosity, pH, density, and compositional analysis. Once results are approved, the batch is released for packaging or shipment.

7. Packaging, Labeling, and Distribution

Many toll processors offer packaging services ranging from bulk totes and drums to pails and smaller containers. Labeling can be customized to meet regulatory and branding requirements. Finished products are then prepared for shipment to the customer or directly to end users.

This end-to-end process allows customers to achieve consistent, repeatable results while minimizing operational risk.

Signs You Should Outsource Blending Instead of Doing It In-House

Deciding whether to outsource chemical blending is both a technical and strategic decision. Several common indicators suggest that chemical blending toll processing may be the right choice.

- Limited production capacity due to space or equipment constraints

- High capital costs associated with purchasing blending equipment

- Inconsistent batch quality or yield issues

- Increasing regulatory and safety compliance burdens

- Fluctuating demand that makes in-house scaling inefficient

- Need for faster time to market for new formulations

Outsourcing allows companies to avoid large upfront investments while gaining access to specialized expertise and infrastructure. It also provides flexibility to scale production up or down as market conditions change.

Chemical Blending Toll Processing for Specialty Chemicals: Common Applications

Chemical blending toll processing is especially valuable in the specialty chemicals sector, where formulations are often complex and quality requirements are stringent. Toll processors support a wide range of applications, including:

- Industrial cleaners and degreasers

- Coatings, sealants, and adhesives

- Lubricants and metalworking fluids

- Water treatment chemicals

- Agricultural and turf products

- Additive packages and performance blends

In these applications, precise ingredient ratios, controlled mixing conditions, and thorough quality testing are essential. Toll processing facilities are designed to handle these demands while maintaining consistency across batches.

Key Questions to Ask a Toll Processor (Lead Times, QC, Packaging)

Choosing the right chemical blending toll processing partner is critical to project success. Asking the right questions during the evaluation process can help ensure alignment and avoid costly issues later.

Important questions include:

- What are typical lead times for blending and packaging?

- What quality control systems and certifications are in place?

- How are raw materials tracked and documented?

- What batch sizes and scalability options are available?

- What packaging formats and labeling services are offered?

- How is intellectual property protected?

- What experience does the facility have with similar products?

A reputable toll processor should be transparent about its capabilities and willing to collaborate closely with your technical and procurement teams.

Contact Us Today

Chemical blending toll processing is a strategic solution for companies seeking flexibility, efficiency, and consistent quality in chemical production. By outsourcing blending to a specialized partner, businesses can reduce capital expenditures, improve operational reliability, and focus on innovation and growth. From specialty chemical formulations to large scale industrial products, toll processing provides a proven pathway to meet market demands without compromising control or quality.

When selecting a partner, experience, quality systems, and technical capabilities should be top priorities. A well-chosen toll processor becomes an extension of your operation, supporting your products from concept through commercialization.

Whether you need custom toll blending services, private label opportunities, or quality chemical formulations for your business, Industrial Technology Corporation is here to meet your needs. Simply contact us today to inquire about our services, request a quote, or discuss your specific requirements. We look forward to working with you to develop innovative solutions that drive success for your business.