What Are the Advantages of Solvent Toll Blending?

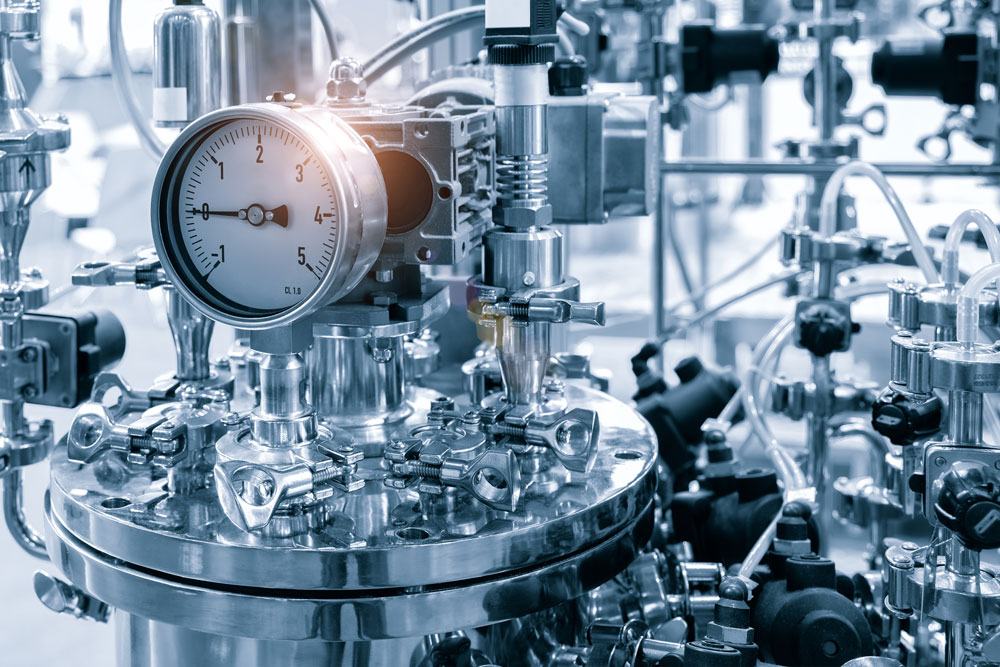

Chemical manufacturing is undergoing a profound shift. As environmental regulations tighten and industries seek safer, more sustainable alternatives, solvent toll blending has evolved beyond simply mixing traditional petroleum-based or hazardous solvents. Today, forward-thinking companies are adopting safe solvents—also referred to as green solvents—to reduce health risks, lower environmental impact, and meet the growing demand for eco-conscious products.

Safe solvents include bio-based, biodegradable, low-toxicity, and low-VOC (volatile organic compound) materials that can replace conventional options in many industrial applications. By combining the precision, safety infrastructure, and efficiency of toll blending with the environmental benefits of green solvents, manufacturers can achieve consistent quality while supporting sustainability goals.

Safety Protocols in Solvent Toll Blending

Working with solvents always requires rigorous safety measures, but the risk profile changes dramatically when shifting from hazardous, flammable, or toxic solvents to safer alternatives. Even though green solvents—such as dimethyl carbonate (DMC), ethyl lactate, bio-based ethanol, or water-based blends—present lower toxicity and reduced environmental hazards, a professional toll blending facility still applies robust safety protocols to ensure product integrity and worker protection.

Hazardous Material Handling in Solvent Toll Blending

While “green” and “safe” solvents minimize health and fire risks compared to traditional options like toluene, xylene, or methylene chloride, some still require controlled handling to prevent exposure or degradation. Toll blenders manage this through:

- Specialized containment and transfer systems that prevent contamination and maintain solvent purity.

- Temperature-controlled storage to prevent degradation of sensitive bio-based solvents.

- Dedicated equipment to avoid cross-contamination between bio-based and conventional solvent lines.

- Tailored PPE protocols to address unique handling needs, even for low-toxicity materials.

The advantage of outsourcing to a toll blender is that your company gains access to facilities already equipped for solvent-specific handling, without having to invest in specialized safety equipment for in-house production. This approach maintains compliance with OSHA and NFPA guidelines while supporting sustainability.

Solvent Recovery in Solvent Toll Blending

Even with safe solvents, efficiency and environmental stewardship remain top priorities. Many bio-based or low-toxicity solvents are still relatively costly to produce, making solvent recovery economically and ecologically beneficial. Toll blending partners often integrate closed-loop recovery systems that reclaim, purify, and reuse green solvents—reducing waste and lowering raw material costs.

Closed-Loop Systems for Solvent Toll Blending

In a closed-loop recovery process for safe solvents, the system may include:

- Low-temperature distillation to protect heat-sensitive bio-based solvents from breakdown.

- Specialized filtration to remove impurities without introducing harsh chemicals.

- Automated quality control to ensure recovered solvent matches original performance specifications.

For example, ethyl lactate—derived from corn or other biomass—can be recovered and reused multiple times without significant degradation, maintaining its excellent solvency power for coatings, inks, or cleaning formulations. This both reduces reliance on new feedstocks and enhances the cost efficiency of green chemistry programs.

By integrating solvent recovery into the toll blending process, manufacturers achieve circular economy benefits—closing material loops while meeting sustainability metrics.

Batch Consistency in Solvent Toll Blending

Green solvents are often used in high-specification products such as eco-friendly paints, low-VOC adhesives, biodegradable cleaning agents, and bio-lubricants. In these applications, batch-to-batch consistency is essential to ensure the final product performs identically across production runs.

Analytical Verification in Solvent Toll Blending

Because safe solvents can have different chemical stability profiles compared to conventional ones, analytical verification is crucial. Toll blenders use laboratory-grade testing to confirm every batch meets defined quality standards, including:

- Purity analysis using gas chromatography (GC) or high-performance liquid chromatography (HPLC).

- Physical property testing, such as viscosity, surface tension, and evaporation rate.

- Performance testing in simulated end-use conditions (e.g., adhesion, drying time, cleaning efficacy).

This is especially important when using renewable-source solvents, where feedstock variability can cause slight differences in raw material composition. Professional toll blending facilities can compensate for these differences with precise formulation adjustments, ensuring repeatable performance for every batch.

Types of Safe and Green Solvents Used in Toll Blending

Safe solvent toll blending can incorporate a wide range of eco-friendly alternatives, each with specific technical advantages:

- Ethyl Lactate – A biodegradable solvent from renewable sources, ideal for coatings, cleaners, and inks.

- Dimethyl Carbonate (DMC) – A low-toxicity, fast-evaporating solvent with excellent solvency for polymers.

- d-Limonene – A citrus-derived solvent with high cleaning power and a pleasant scent, often used in degreasers.

- Bio-based Ethanol or Isopropanol – Renewable alcohol solvents for cleaning, extraction, and formulations.

- Propylene Carbonate – A low-VOC, biodegradable solvent used in adhesives and electronics applications.

- Water-Based Solvent Systems – For emulsions and dispersions that replace high-VOC blends entirely.

By selecting the right green solvent for the job, manufacturers can reduce worker exposure risks, improve environmental performance, and align with green certification standards such as the EPA’s Safer Choice or EU Ecolabel.

The Integrated Advantage: Safety, Sustainability, and Quality

When safe solvents are paired with the advanced capabilities of a professional toll blending partner, the benefits multiply:

- Lower workplace hazard potential due to the inherent safety profile of green solvents.

- Reduced environmental footprint from closed-loop recovery and renewable feedstocks.

- Consistent quality control backed by scientific analysis and formulation expertise.

- Faster regulatory compliance with green chemistry and low-VOC product mandates.

This integrated approach allows companies to bring sustainable products to market without sacrificing performance or operational efficiency.

Additional Operational Advantages of Safe Solvent Toll Blending

The switch to safe solvents doesn’t just deliver environmental and safety benefits; it can also enhance your competitive position:

- Brand differentiation – Products formulated with green solvents can be marketed as eco-friendly, meeting consumer demand for sustainable goods.

- Regulatory readiness – Anticipating future restrictions on hazardous solvents helps avoid reformulation crises.

- Market access – Many government and institutional buyers now require low-VOC or non-toxic formulations.

- Innovation support – Toll blenders with green chemistry expertise can assist in developing new, high-performance formulations that meet sustainability goals.

Partner with Industrial Technology Corporation

Solvent toll blending using safe and green solvents is not just an environmentally responsible choice; it’s a competitive, forward-thinking manufacturing strategy. By combining lower-risk solvents with the precision and infrastructure of professional toll blending, your business can achieve outstanding product performance, reduce environmental impact, and protect worker safety.

Whether you need custom toll blending services with green solvents, private label opportunities, or high-quality, eco-friendly chemical formulations for your business, Industrial Technology Corporation is here to meet your needs. Simply contact us today to inquire about our services, request a quote, or discuss your specific requirements. We look forward to working with you to develop innovative, sustainable solutions that drive success for your business.